At the heart of Hi-technology’s capabilities lies our plastic injection moulding expertise, built on over four decades of hands-on experience. We specialise in delivering both intricate low-volume components and high-volume production runs using fully automated systems. Our operational footprint spans three strategic sites across the UK (Waterlooville and Letchworth) and Slovakia, equipped with a comprehensive range of injection moulding presses all the way from 25 to 650 tonnes.

Plastic Injection Moulding

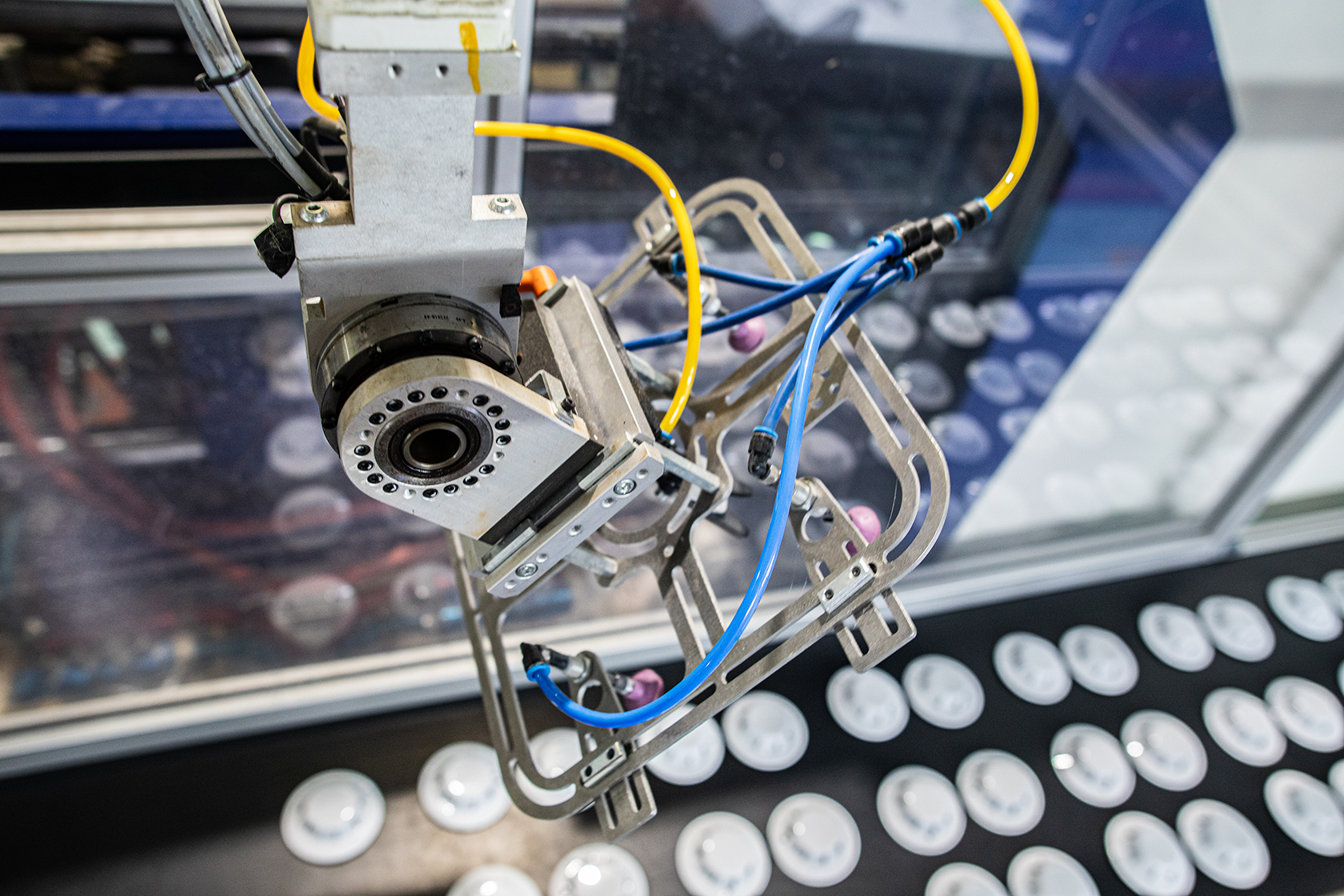

Our technical capability also extends to a wide array of specialist manufacturing solutions. These include ultrasonic welding services and vertical presses with integrated vision systems designed for the precision over-moulding of delicate connectors, as well as in-mould decoration and various custom over-moulding processes.

When moulding, we work with a broad spectrum of thermoplastic materials, from standard polymers to advanced, high-performance compounds. These include

challenging engineering plastics such as PEEK, polymer alloys, and other high-end resins known for their thermal, mechanical, and chemical resistance properties.

Whether your project demands strict dimensional tolerances, aesthetic precision, or enhanced mechanical performance, our expert team can tailor a moulding solution to meet the most demanding specifications.

We support a diverse range of sectors. from medical injection moulding to automotive, aerospace, and consumer products – ensuring every industry benefits from the same precision, consistency, and quality assurance.