As a full-service contract manufacturer serving demanding clients in highly regulated industries, quality is at the core of everything we do. Our ISO 9001-certified quality management system forms the foundation of our operations, ensuring that our products and services consistently meet the highest standards. This commitment to quality gives our clients the confidence that they are in capable, reliable hands.

A Quality-First Moulder

Comprehensive Quality Assurance

All key aspects of product setup, sourcing, manufacturing, inspection, and delivery are tightly controlled within our operations. This includes the management of engineering masters, drawing revisions, setting documents, work orders, visual aids, as well as assembly and testing instructions. We also support our clients’ specific ISO requirements, such as ISO 13485 for medical devices and meet the rigorous demands of sectors like Defence and Aerospace, including full traceability and production approvals.

Flexible Qualification & Validation

We offer a full suite of qualification processes and documentation tailored to each customer’s unique requirements. Some clients may only need a basic Initial Sample Inspection Report (ISIR) and samples, while others require a full Production PartApproval Process (PPAP) submission.

Whether it’s scientific moulding, capability studies (Cpk) across various processes, Measurement System Analysis (MSA), Design of Experiments (DOE), customer specific First Article Inspection Reports (FAIR), or full PPAPs, we are equipped to deliver.

Our flexible approach allows us to adapt to individual needs including validating mouldings to specific presses when necessary and conducting full revalidation for transfer tooling.

Proactive Quality Control

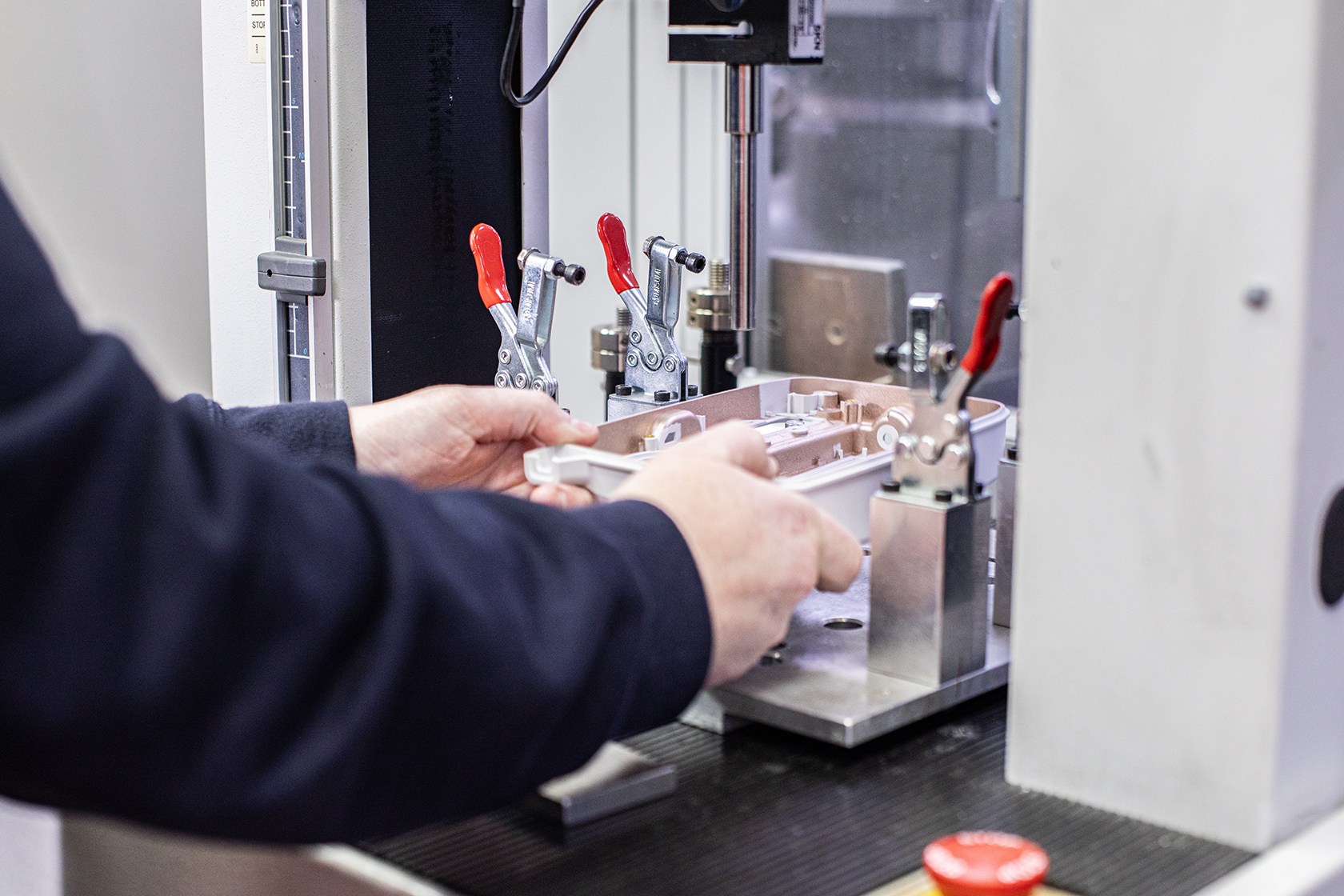

In the plastic injection moulding and product assembly environment, constant monitoring is essential, even small process shifts, or operator changes can impact quality. At Hi-technology, we have a full team of roving inspectors, with a clear remit for regular checks on all product lines. This proactive approach is reinforced by a strict first-off approval process, clearly defined visual standards and thorough end-of-line testing.

Together, these measures ensure we consistently deliver the high level of quality our customers expect from us.