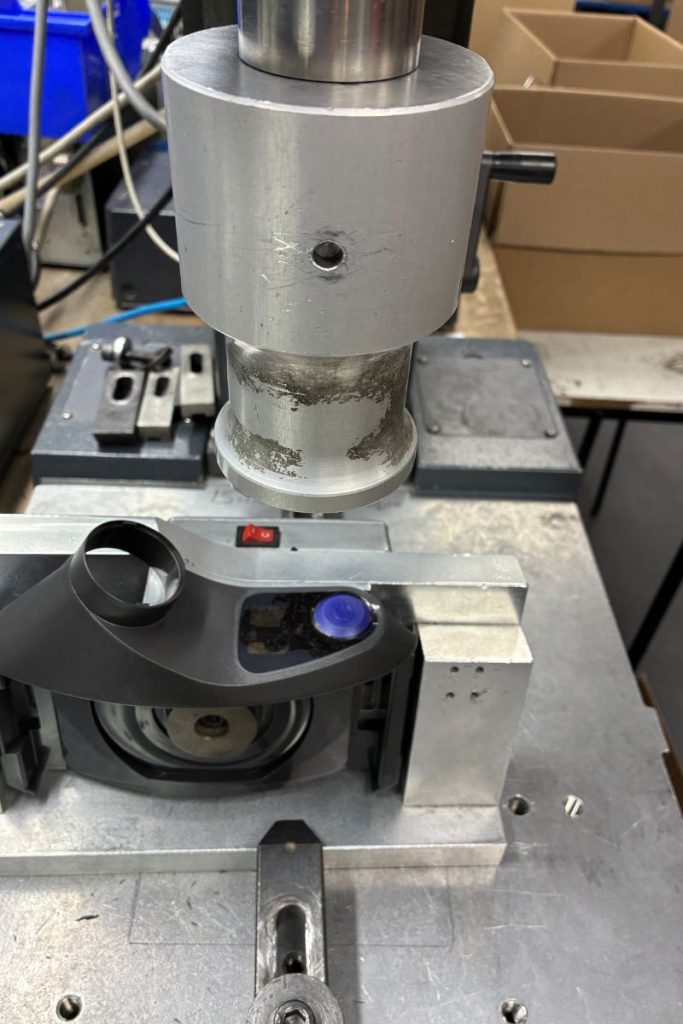

Ultrasonic welding has become one of the most reliable and efficient methods for joining thermoplastics in precision manufacturing. It’s fast, clean, and strong, ideal for industries where quality and consistency are non-negotiable, such as medical, aerospace, defence, and electronics.

At Hi-Tech Mouldings, we offer ultrasonic welding services as part of our full-service manufacturing solution, integrating it seamlessly with injection moulding and assembly operations across our UK and European facilities.